R35 Ring Die Pellet Mill

30 HP or 50 HP Motor

$39,000.00

Efficiency Unleashed: The MILL-R35 Economical Ring Die Pellet Mill

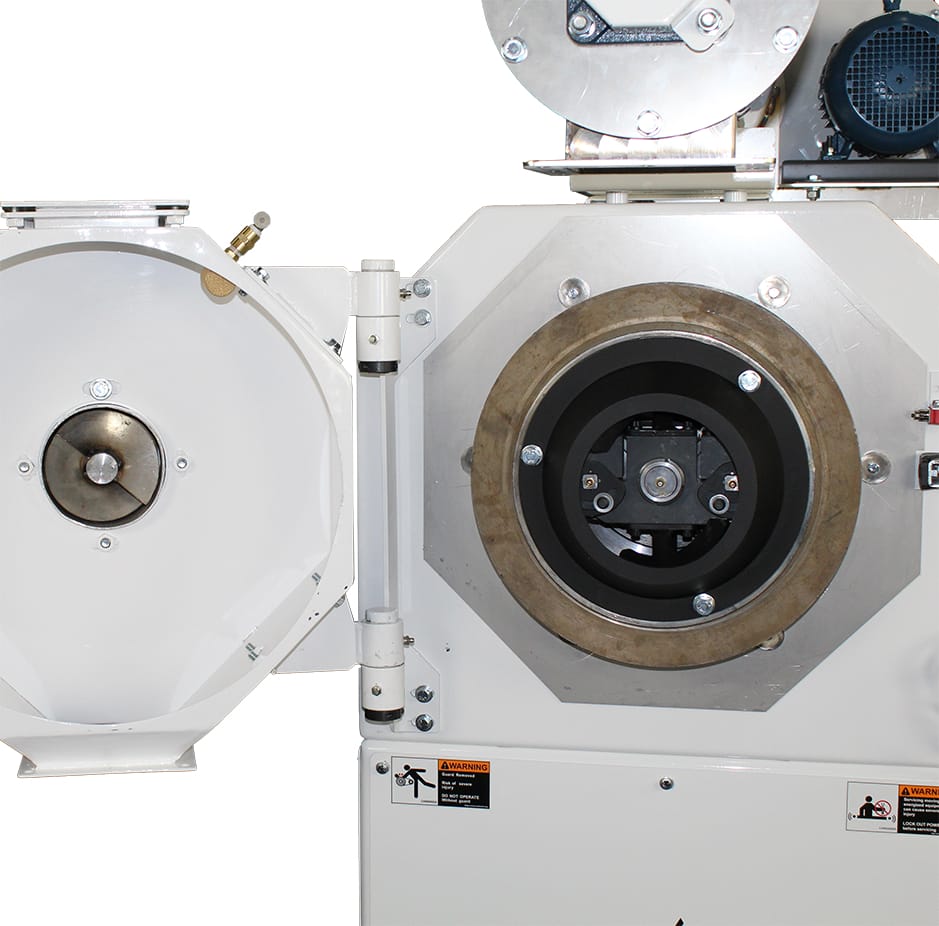

The R35 is an economical pilot-to-production scale ring die pellet mill that boasts a dependable belt drive system and has the capacity to produce 500 to 2500 lbs per hour, depending on the material.

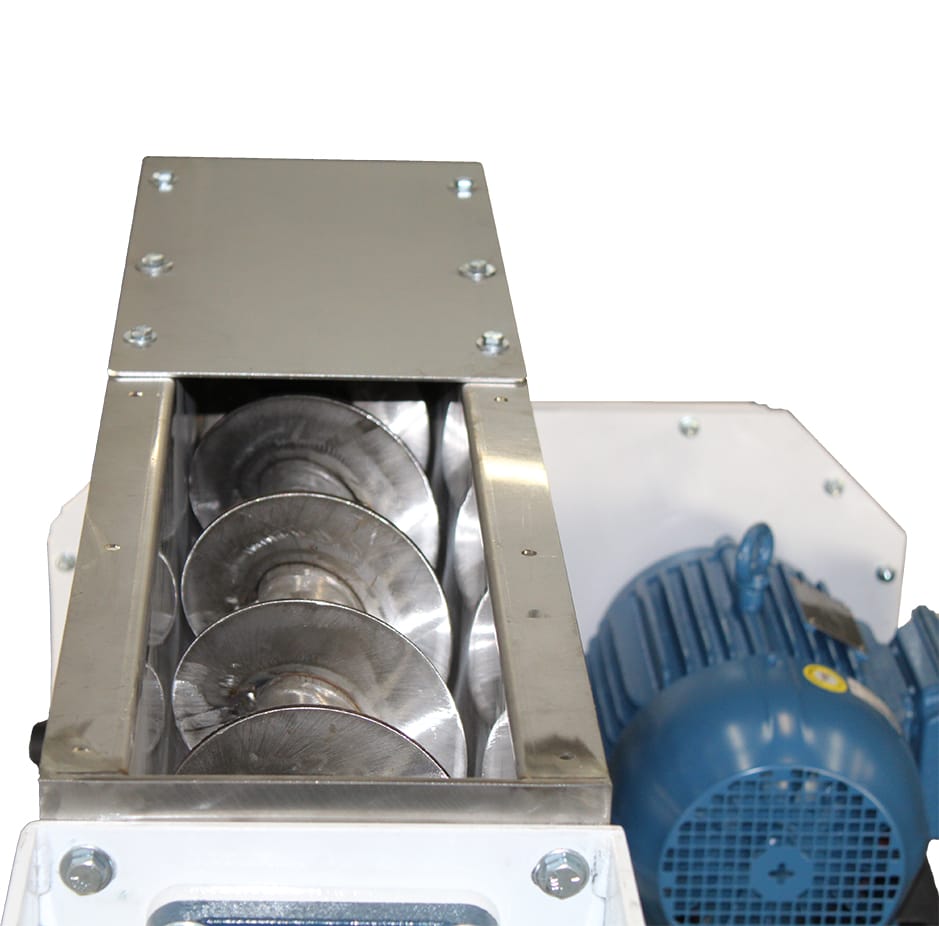

The unit features a 30 HP motor and includes a stainless steel door, gravity feed chute, one set of rolls, and an adjustable cut-off knife. Customization options for the R35 include a stainless steel feeder, an adjustable paddled stainless steel conditioner, force feeder, and die.

* Options shown in images and/or videos are sold separately and not included in price.

Motor

30 HP & 50 HP

Capacity/HR

500-2,500 LBS

Die Inner Dia.

10″ Ring

Dimensions

75” L x 35” W x 85” H

Weight

2550 LBS

- Equipped with 30 HP TEFC, 3-phase motor

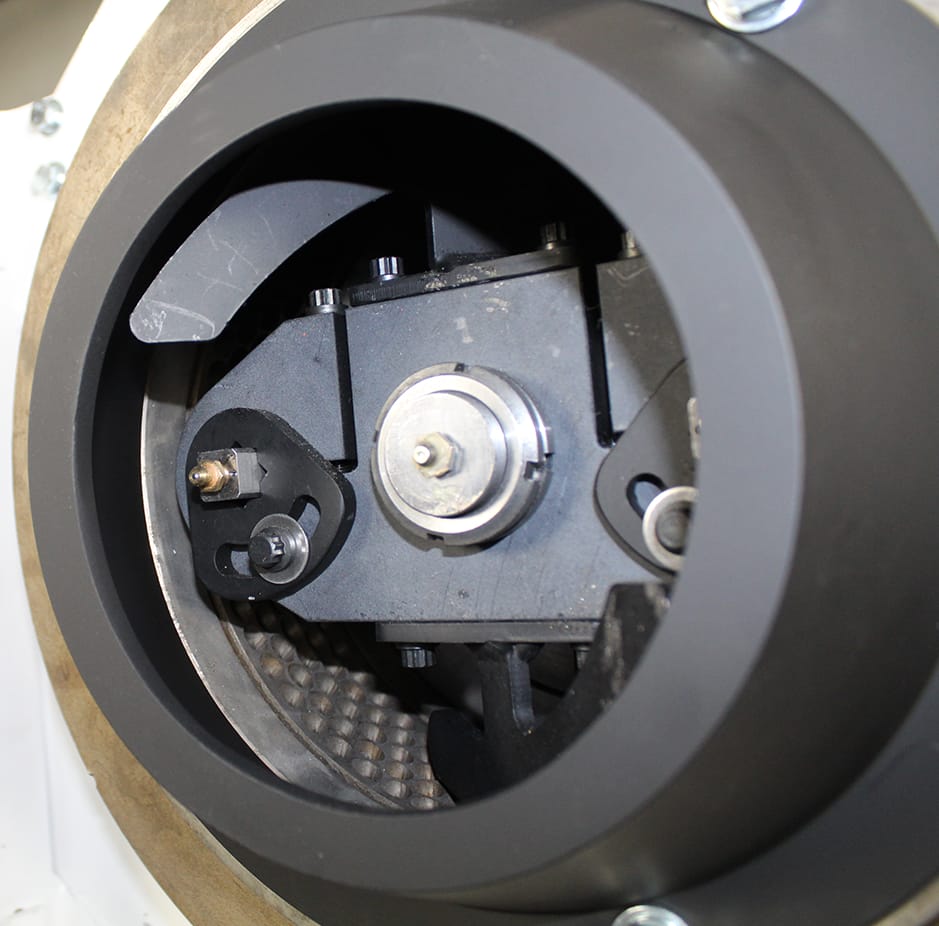

- New dies available: 1/8” to 1/2”

- Custom die sizes available upon request

- Simple and reliable belt drive system

- Mounted on a steel frame

- Safety stickers with icons

- Safety guards over all pulleys and bearings

- Stainless steel hinged door with safety interlock

- Easy-adjust knife posts to change pellet length

- Feed-chute with hinged door for lab runs/die clean-out

- Operator’s manual included

- Designed, assembled, & supported in the USA

- CME’s Signature 1-Year Manufacturer’s Warranty

- Drylac Powder Coating compliant to FDA 21 CFR 175.300

- Change Parts Required: New Die

- Change Parts Required: Roller Assembly Set

- Stainless Conditioner

- Stainless Feeder with Inverter Duty Motor

- Force Feeder

- Isolation Pad Set

- Nitrogen Ports

- Food Grade Grease

- Safety Control Panel

- Alfalfa

- Corn

- General Feed

- Hemp/Cannabis

- Oats

- Plastics

- Poultry Litter

- Soybean Meal

- Wheat

- Fertilizer

- Carbon

CME Is Your Best Choice

America First Manufacturing

Colorado Mill Equipment is an innovative company dedicated to providing high-quality, Made in USA pelletizing, milling, and bagging equipment to meet the needs of a global industry. We are equipped to run tests on a wide variety of products, refurbish equipment, supply spare parts, and ship machinery internationally.

Parts are made and stocked in the USA, at our own facility

We offer a “test your material before you buy” option

In-house training included with every pellet mill purchase

Lifetime technical, application, and engineering support