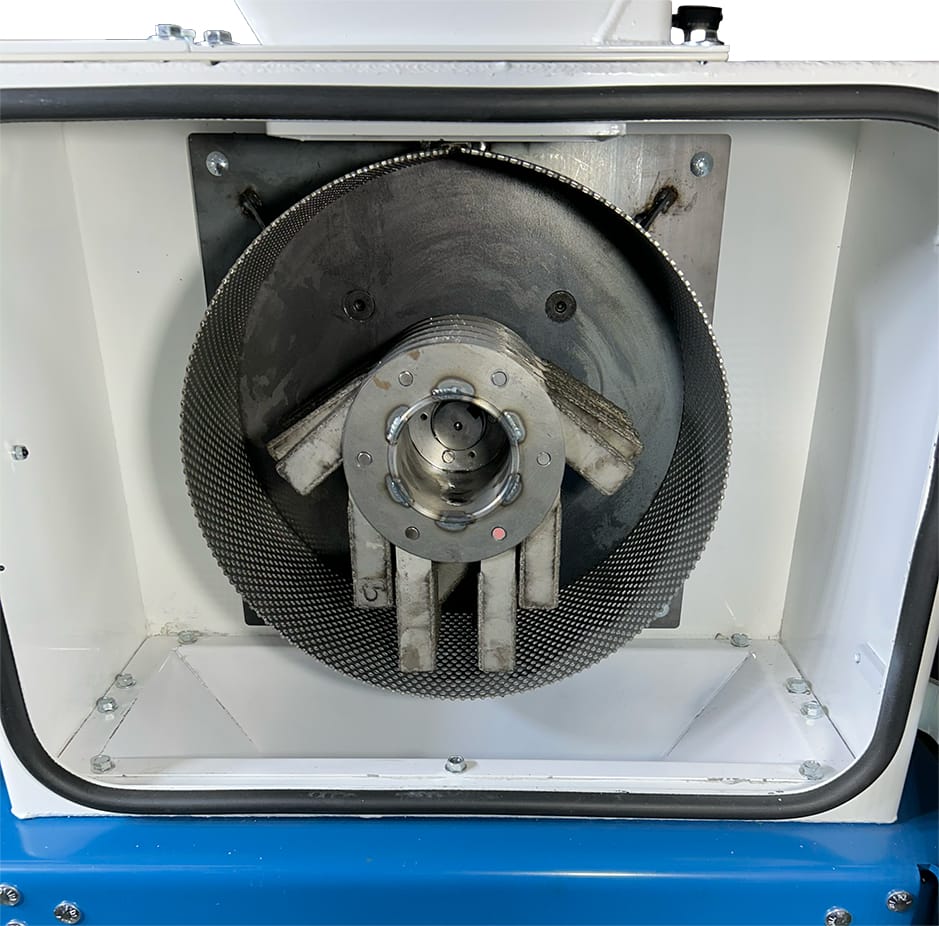

HMW Hammer Mill

50 HP Motor

Starting at $19,500

Discover High-Capacity Grinding with CME’s Hammer Mill Technology

Experience the strength of the HMW 50HP hammer mill grinder by CME. Designed for heavy-duty performance, this hammer mill delivers efficient grinding with versatile applications from lump breaking to fine grinding. Offering reliable output for both wet and dry processes, the HMW model is built to handle demanding production with ease.

Pair with the HMS Air System

Boost efficiency and safety by pairing the HMS-VB Hammermill with CME’s Air System add on.

* Options shown in images and/or videos are sold separately and not included in price.

Motor

50 HP

Capacity/HR

Please call for the capacity of your application

Aspiration Req.

600 CFM

Screen Size

.020” – 1”

Screen Area

460″

Hammers:

60

Dimensions

48″ L x 48″ W x 62″ H

Weight

2000 LBS

- Stainless steel contact parts

- Quick change stainless single screen design

- Fine grinding down to 200 microns

- True full circle screen design

- Includes new set of stainless hammers

- Hinged door with easy access hammers & screen

- Safety door latch with lock included

- One cubic foot stainless hopper with slide gate

- Equipped with a 50 HP TEFC motor, with stainless shaft

- Unit includes 300 CFM safety vent

- Auto shut off safety interlock

- Change Parts Required: New Screen

- Magnet

- Isolation Pad Set

- Safety Motor Starter

- XP Motors

- Drylac Powder Coating compliant to FDA 21 CFR 175.300

- Required Change Parts: Hammers & Screens

- Magnet*

- Vibration Switch*

- Safety Motor Starter*

- Isolation Pad Set*

- Air System with Filter

- Single Phase Motor (3 & 10 HP only)

- Safety Motor Starter

- XP Motors

- Extension Legs – $1,200

*Recommended for optimal performance and safety

- Alfalfa

- Corn

- General Feed

- Hemp/Cannabis

- Oats

- Poultry Litter

- Soybean Meal

- Wheat

- Fertilizer

- Carbon

- Recyclables

- Wood

- Wood Grill Pellets

CME Is Your Best Choice

America First Manufacturing

Colorado Mill Equipment is an innovative company dedicated to providing high-quality, Made in USA pelletizing, milling, and bagging equipment to meet the needs of a global industry. We are equipped to run tests on a wide variety of products, refurbish equipment, supply spare parts, and ship machinery internationally.

Parts are made and stocked in the USA, at our own facility

We offer a “test your material before you buy” option

In-house training included with every pellet mill purchase

Lifetime technical, application, and engineering support