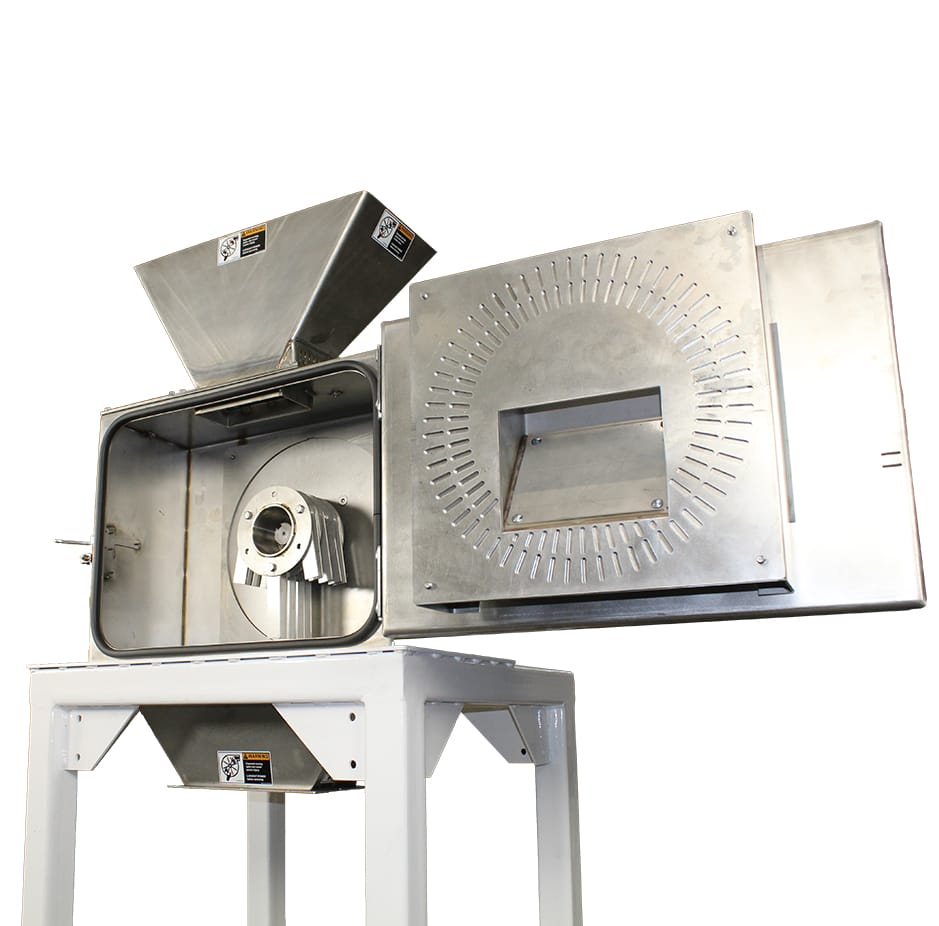

MILL-HMS-VB10-SS, 10HP Stainless Steel Hammermill

SKU # MILL-HMSVBSS10

$19,000.00

Unleash Power and Performance: Hammermax Series Hammermills

CME’s Stainless Steel MILL-HMS-VB10-SS is a versatile hammermill designed for gravity discharge and capable of grinding a wide range of products. It can be equipped with a 3, 10, or 30 HP motor, offering flexibility for different applications.

This hammermill serves multiple purposes, functioning as a lump breaker, standard hammermill, or fine grinder, making it suitable for both wet and dry grinding tasks.

* Options shown in images and/or videos are sold separately and not included in price.

Motor

10 HP

Capacity/HR

Please call for the capacity of your application

Aspiration Req.

500 CFM

Screen Size

.20″ to 3″

Screen Area

368″

Hammers:

15

Dimensions

48″ L x 48″ W x 62″ H

Weight

800 LBS

- Stainless steel contact parts

- Quick change stainless single screen design

- Fine grinding down to 200 microns

- True full circle screen design

- Includes new set of stainless hammers

- Hinged door with easy access hammers & screen

- Safety door latch with lock included

- One cubic foot stainless hopper with slide gate

- Equipped with a 10 HP TEFC motor, with stainless shaft

- Unit includes 300 CFM safety vent

- Auto shut off safety interlock

- Telescoping Legs

- Safety stickers with icons

- Drylac Powder Coating compliant to FDA 21 CFR 175.300

- Designed, built, & supported in the USA

- CME’s Signature 1-Year Manufacturer’s Warranty

- Change Parts Required: New Screen

- Magnet

- Isolation Pad Set

- Single Phase Motor (3 & 10 HP only)

- Safety Motor Starter

- XP Motors

- Extension Legs – $1,200

- Alfalfa

- Corn

- General Feed

- Hemp / Cannabis

- Oats

- Poultry Litter

- Recyclables

- Soybean Meal

- Wheat

- Wood

- Wood Grill Pellets

- Fertilizer

- Carbon

CME Is Your Best Choice

America First Manufacturing

Colorado Mill Equipment is an innovative company dedicated to providing high-quality, Made in USA pelletizing, milling, and bagging equipment to meet the needs of a global industry. We are equipped to run tests on a wide variety of products, refurbish equipment, supply spare parts, and ship machinery internationally.

Parts are made and stocked in the USA, at our own facility

We offer a “test your material before you buy” option

In-house training included with every pellet mill purchase

Lifetime technical, application, and engineering support

Recommended Products

Assembled in the USA

Our equipment is engineered and supported in the USA