MILL-HMA125 Hammer Mill

SKU # MILL-HMA125

Call for Pricing

Customize Your Grinding Experience with HMA125 Hammermill Machine

The HMA125 Hammermill machine from the Millennium Series by Colorado Mill Equipment offers the choice between a blower or gravity discharge setup. Blower discharge is ideal for fibers and lighter materials, while heavier grains and minerals can operate effectively with either configuration. This machine is designed to accommodate a motor power range of 50 HP to 125 HP.

* Options shown in images and/or videos are sold separately and not included in price.

Motor

50, 75, 100, 125 HP

Capacity/HR

Please call for the capacity of your application

Aspiration Req.

Screen Size

.020″ to 1″

Screen Area

764″

Hammers:

28

Dimensions

98″ L x 42″ W x 59″ H

Weight

3,500 LBS

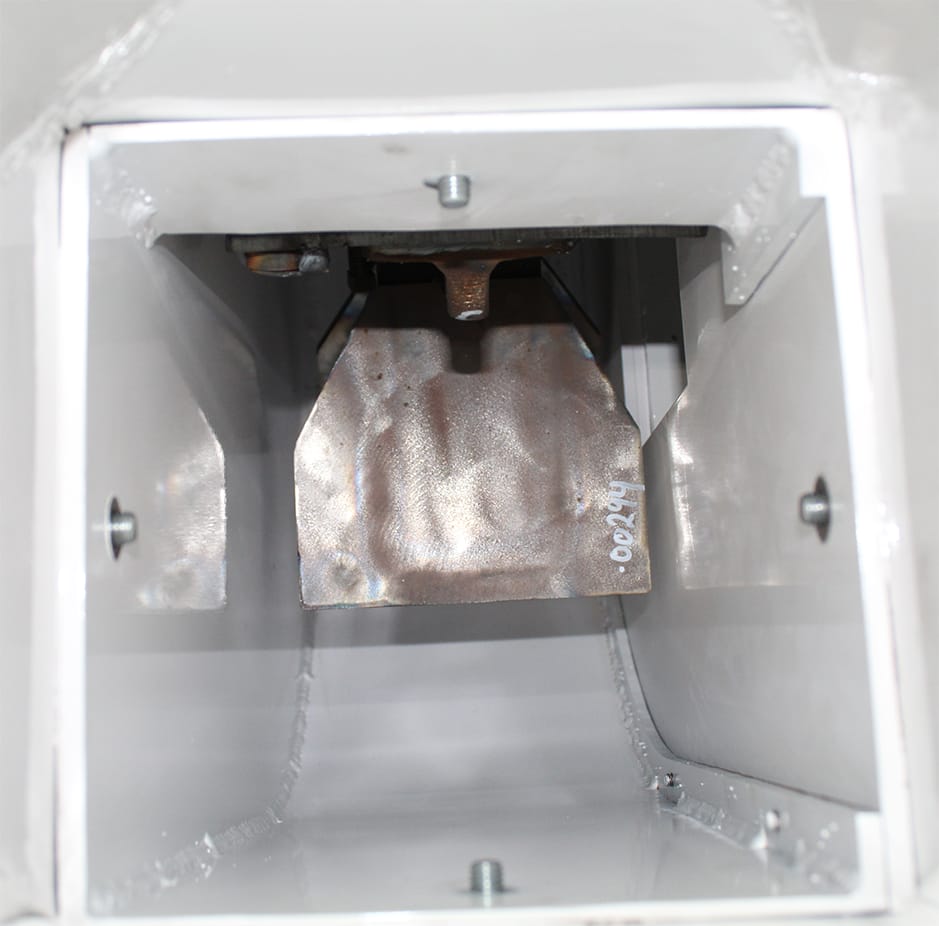

- Quick change single screen design

- Extra large 12” x 20” opening

- 50, 75, 100, or 125 HP TEFC motor

- Easy-open split-top design

- Industrial grid-style coupling

- Heavy duty 3/8” thick industrial hammers

- Wear liners on sides and breaker plate on top

- Safety guards and safety stickers with icons

- Rotor assembly that requires no spacers

- Efficient air-assist grinding system

- Super heavy-duty mild steel base

- Drylac Powder Coating compliant to FDA 21 CFR 175.300

- Designed, built, & supported in the USA

- CME’s Signature 1-Year Manufacturer’s Warranty

- Available with or without a blower

- Change Parts Required: New Screen

- Cyclone Air System

- Magnet for Metal Removal

- Isolation Pad Set

- Safety Control Panel

- 575V Motors

- Blower or Gravity Setup

- Alfalfa

- Corn

- General Feed

- Hemp / Cannabis

- Oats

- Poultry Litter

- Recyclables

- Soybean Meal

- Wheat

- Wood

- Wood Grill Pellets

- Fertilizer

- Carbon

CME Is Your Best Choice

America First Manufacturing

Colorado Mill Equipment is an innovative company dedicated to providing high-quality, Made in USA pelletizing, milling, and bagging equipment to meet the needs of a global industry. We are equipped to run tests on a wide variety of products, refurbish equipment, supply spare parts, and ship machinery internationally.

Parts are made and stocked in the USA, at our own facility

We offer a “test your material before you buy” option

In-house training included with every pellet mill purchase

Lifetime technical, application, and engineering support

Recommended Products

Assembled in the USA

Our equipment is engineered and supported in the USA