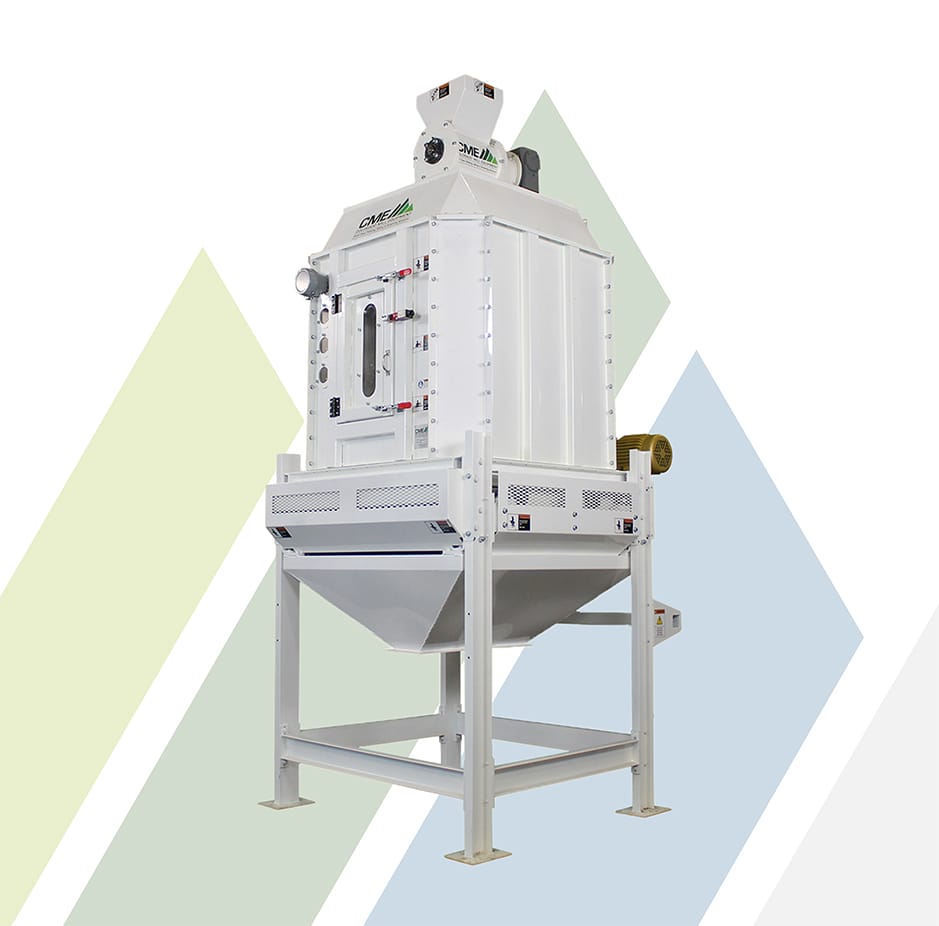

C4 Pellet Cooler

Equipped With a 2HP Drive

Call for Pricing

The C4 Pellet Cooler: Efficient Cooling for 1-4 Tons of Pellets per Hour

Experience exceptional cooling with the C4 Pellet Cooler, designed to handle up to 4 tons of pellets per hour. Its performance is influenced by factors like pellet size, density, temperature, and composition. The unit comes equipped with a 1000 x 1000mm variable swing discharge grid, offering a dwell time of around 8 to 15 minutes. The showcased unit showcases optional features including an air system, rotary airlock, cyclone, and discharge chute, enhancing its functionality and versatility.

The unit includes a 1000 x 1000 mm variable swing discharge grid with a dwell time of approximately 10 – 15 minutes. Unit shown features the optional air system, rotary airlock, cyclone, and discharge chute

* Options shown in images and/or videos are sold separately and not included in price.

Capacity / HR

1- 4 TONS

Variable Swing Discharge Grid

1000 x 1000 mm

Included Level Sensor

Yes

Approx. Dims.

47″ L x 44″ W x 129″ H

Weight

1,800 LBS

- Variable swing discharge grid

- Heavy-duty construction

- Easy maintenance

- Equipped with a 2 HP motor

- Heavy-duty Cleveland gearbox

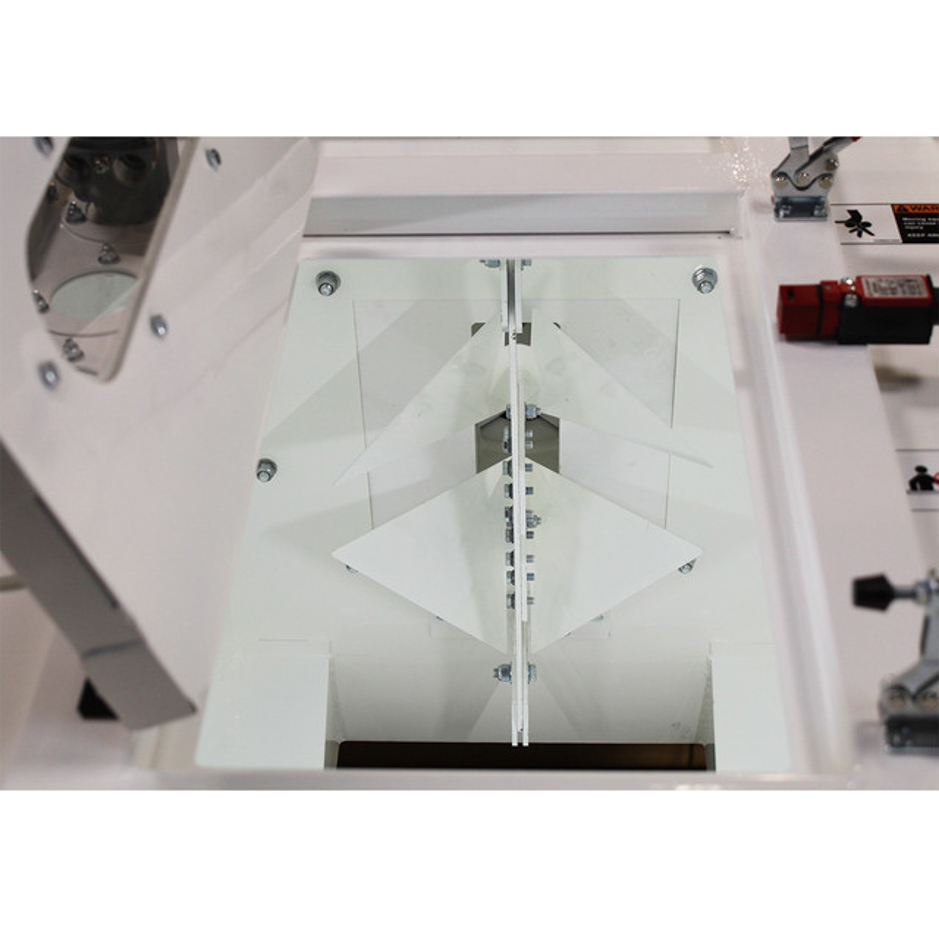

- Ultra diffusion spreader with 4 way adjustment

- Triple grid system for minimal product breakage

- Ultra compact footprint

- Drylac Powder Coating compliant to FDA 21 CFR 175.300

- Manway Door

- Safety interlock

- Designed, built, & supported in the USA

- CME’s Signature 1-Year Manufacturer’s Warranty

- Required component (select one): Discharge Chute for use with Screener or Gravity Discharge Chute

- SCR34 Screener

- Top Airlock

- Cyclone Airlock

- Air System (Blower Stand, Cyclone, Ductwork)

- Isolation Pad Set

- Safety Control Panel

- Cubing Grid

- Alfalfa

- Corn

- General Feed

- Hemp/Cannabis

- Oats

- Poultry Litter

- Soybean Meal

- Wheat

- Fertilizer

- Carbon

- Wood

- Wood Grill Pellets

- Plastics

CME Is Your Best Choice

America First Manufacturing

Colorado Mill Equipment is an innovative company dedicated to providing high-quality, Made in USA pelletizing, milling, and bagging equipment to meet the needs of a global industry. We are equipped to run tests on a wide variety of products, refurbish equipment, supply spare parts, and ship machinery internationally.

Parts are made and stocked in the USA, at our own facility

We offer a “test your material before you buy” option

In-house training included with every pellet mill purchase

Lifetime technical, application, and engineering support