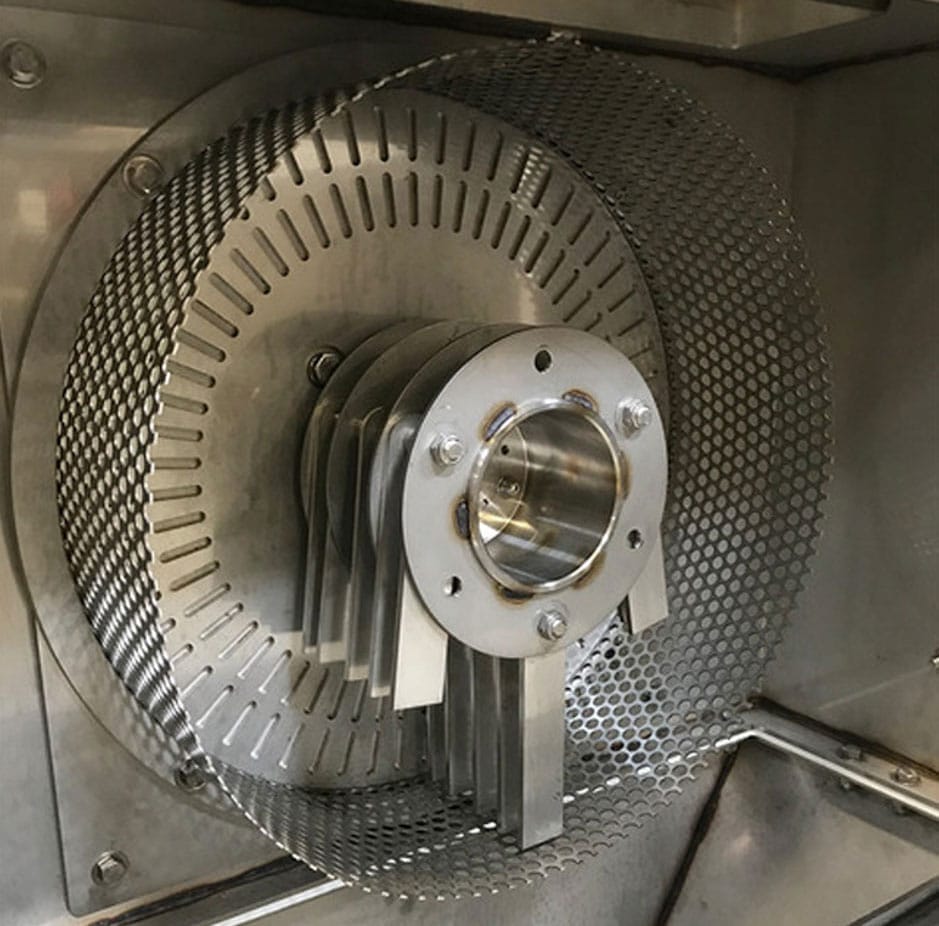

HMS-VB Series Stainless Steel Hammer Mill

3, 10, or 30–40 HP motors

Starting at $17,500

Precision Grinding with Stainless Steel Hammer Mill Technology

The CME HMS VB Series Stainless Steel Hammer Mills are built in the USA for durability, hygiene, and precision. Available with 3, 10, or 30–40 HP motors, these hammermills provide gravity discharge grinding for a wide range of materials with the added strength of stainless steel construction.

Each model is designed for versatility, operating as a lump breaker, standard hammer mill, or fine grinder. With the ability to achieve particle sizes down to 200 microns, the Stainless Steel HMS VB Series delivers consistent results for both wet and dry applications in feed, biomass, recycling, and food-grade processing industries.

Built to meet demanding production needs, these stainless steel hammer mills combine durability and sanitation in one powerful machine.

* Options shown in images and/or videos are sold separately and not included in price.

Motor

3-40 HP

Capacity/HR

Up to 30,000 lbs/hr

*call for capacity on your application

Aspiration Req.

500 CFM

Screen Size

.020″ to 1″

Screen Area

368″²

Hammers:

15-30

Dimensions

48″ L x 48″ W x 62″ H

Weight

750-1500 LBS

- Hammers & Screens*

- Magnet*

- Vibration Switch*

- Safety Motor Starter*

- Isolation Pad Set*

- Air System with Filter

- Single Phase Motor (3 & 10 HP only)

- XP Motors

- Extension Legs

*Recommended for optimal performance and safety

- Fine grinding capability down to 200 microns

- True full-circle screen design for maximum efficiency

- Quick-change single screen design (swap in 30 seconds)

- One cubic foot hopper with slide gate

- Hinged door with easy access to hammers & screen

- Uses our super duty carbide hammers

- Equipped with a TEFC motor

- Built-in 300 CFM safety vent

- Auto shut-off safety interlock

- Safety door latch with lock

- Safety stickers with icons

- Durable Drylac powder coating, compliant with FDA 21 CFR 175.300

- Alfalfa

- Corn

- General Feed

- Hemp/Cannabis

- Oats

- Poultry Litter

- Soybean Meal

- Wheat

- Fertilizer

- Carbon

- Recyclables

- Wood

- Wood Grill Pellets

CME Is Your Best Choice

America First Manufacturing

Colorado Mill Equipment is an innovative company dedicated to providing high-quality, Made in USA pelletizing, milling, and bagging equipment to meet the needs of a global industry. We are equipped to run tests on a wide variety of products, refurbish equipment, supply spare parts, and ship machinery internationally.

Parts are made and stocked in the USA, at our own facility

We offer a “test your material before you buy” option

In-house training included with every pellet mill purchase

Lifetime technical, application, and engineering support